Style Sampler

Layout Style

Search News Posts

General Inquiries 1-888-555-5555

•

Support 1-888-555-5555

Inventory Forecasting

A retail company selling electronics and appliances is facing a challenge in managing their inventory. They often run out of stock, leading to lost sales opportunities, while at other times, they have an excess of inventory, leading to excess carrying costs. To address this issue, they have decided to implement an inventory forecasting system.

The first step in building an inventory forecasting model is to collect historical sales data. The company collected data on sales for the past two years, including the quantity sold, the date of sale, and the price of each item sold. They also collected data on the promotions and marketing campaigns that were run during this period.

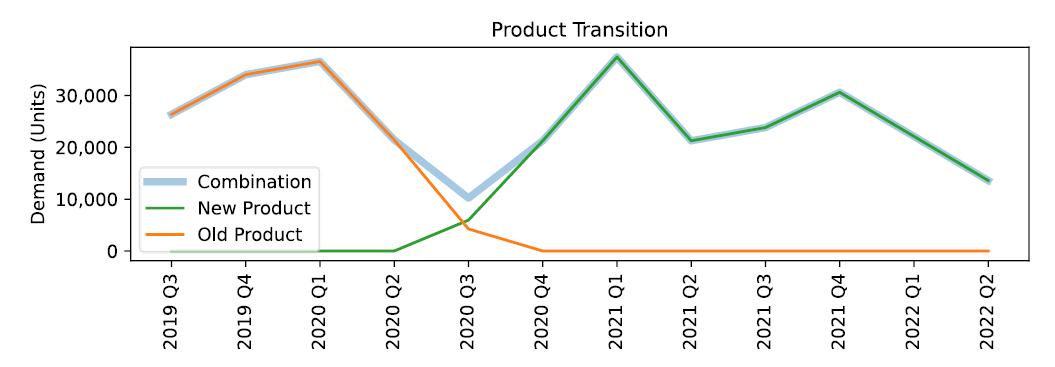

The data was analyzed to identify trends and patterns in sales, such as seasonality, trends, and spikes. Seasonality was identified by analyzing the data for sales of each item by month and week. Trends were identified by analyzing the overall sales data for each item over the two-year period. Spikes were identified by analyzing the data for promotions and marketing campaigns.

The company used machine learning algorithms to develop a forecasting model. They chose to use a time-series analysis algorithm that would account for seasonality and trends. The model was trained on the historical sales data and used to forecast future sales.

The accuracy of the forecasting model was validated by comparing the forecasted sales with the actual sales. The model was adjusted as necessary to improve its accuracy.

The forecasting model was integrated into the company's inventory management system. The system automatically generates purchase orders based on the forecasted sales, ensuring that the company has the right amount of inventory at the right time.

After implementing the inventory forecasting system, the company saw significant improvements in their inventory management. They were able to reduce the number of stockouts and excess inventory, leading to a reduction in carrying costs. They also saw an increase in sales due to improved product availability.

Let’s get in touch to see how much value advanced forecasting can deliver to your supply chain.